Articles

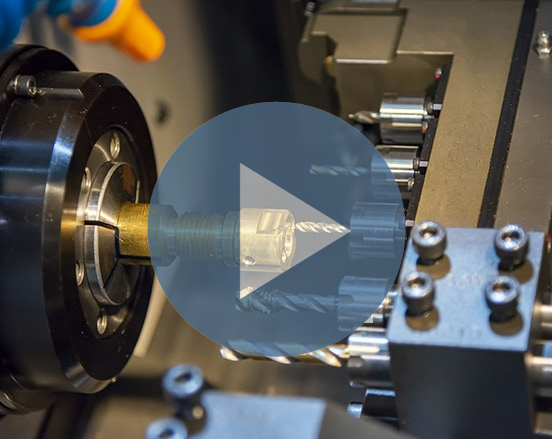

Complex Part Produced with One Setup

This aluminum part was produced with one setup. Note the intricate geometry, recessed bores, counterbores, threaded grooving with tapered bores. A bike manufacturer needed a

Large, Multi-Axis Aluminum Part

An engine manufacturer was in need of a valve body made with an aluminum alloy. The part was designed with O-ring ports for connecting fluid

Multi-Axis, Ultra-Small Titanium Parts

A manufacturer of military aerospace products required tiny titanium parts. The specifications required the parts to be produced with multiple angles, through holes and counterbores.

Milled Plastic Medical Parts

A medical parts distributor was in need of a field surgical device. The tool was to be made of plastic that would seal to keep

Boyer Embarks on AS9100D Certification

Boyer Machine and Tool (Boyer), a key player in precision manufacturing, is proud to announce its pursuit of the AS9100D certification. This industry-standard Quality Management

About Wire EDM

Wire EDM (Electrical discharge machining), also known as spark machining or spark eroding, is a manufacturing process of creating a desired part from the metal