Tiny Aeronautics Component Produced with Multi-axis Swiss Machining

An aeronautics manufacturer was in need of a tiny stainless steel component. The part had an intricate design with a hexagon head and a tapered lip, a hole centered through the neck and a recessed base that needed to fit snugly with an adjoining part. This stainless steel part was perfect for Boyer’s Swiss machining […]

Complex 316 Stainless Steel Part Produced in One Setup

A manufacturer was in need of a 316 stainless steel part that worked in a fluid control machine. The part was complex, with multiple channels and counterbores. The tolerances were very tight. Boyer Machine specializes in machining complicated and detailed metal parts to their print specifications. In this case, Boyer machined this fluid control part […]

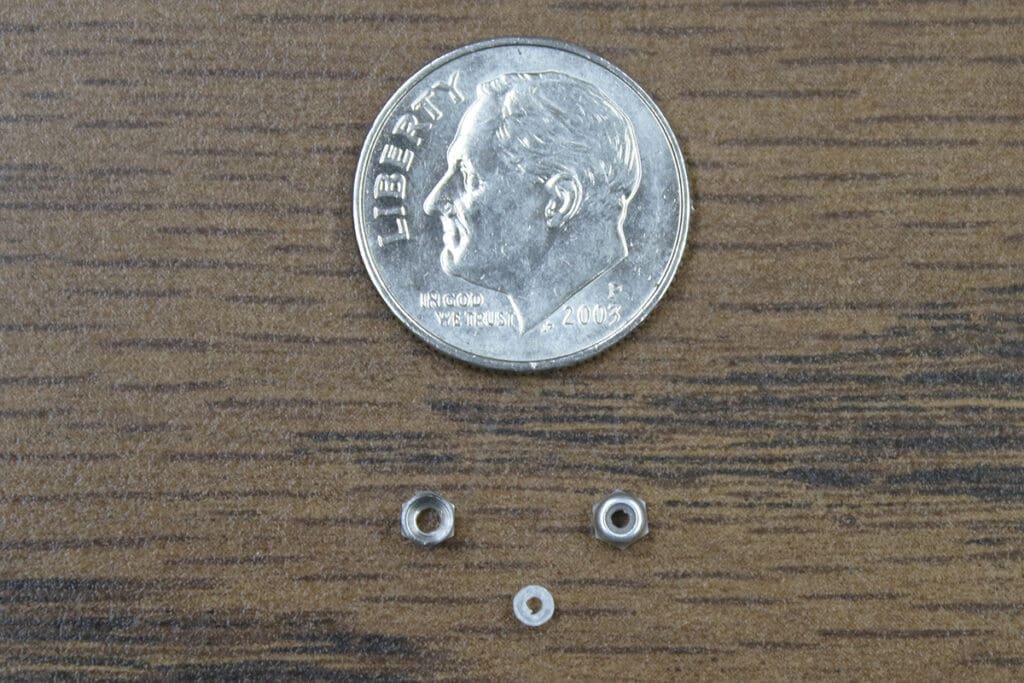

Tiny aerospace part combines stainless steel and laser-cut nylon components

An aerospace manufacturer was in need of very tiny nuts for an assembly. The nuts were specified to be built with 303 stainless steel. But the very tedious process also required the tooling of a nylon insert that would be placed precisely inside each nut. Boyer specializes in machining both complex metal and plastic parts. […]

Large, Multi-Axis Aluminum Part

An engine manufacturer was in need of a valve body made with an aluminum alloy. The part was designed with O-ring ports for connecting fluid lines, bores for sensors and other components. They needed only a few hundred of these parts produced. This part had very tight tolerances for the size and location of features […]

Multi-Axis, Ultra-Small Titanium Parts

A manufacturer of military aerospace products required tiny titanium parts. The specifications required the parts to be produced with multiple angles, through holes and counterbores. The customer also needed a small quantity run on these parts. Boyer Machine specializes in small, milled parts. They have decades of experience machining complex metal alloys that other machine […]