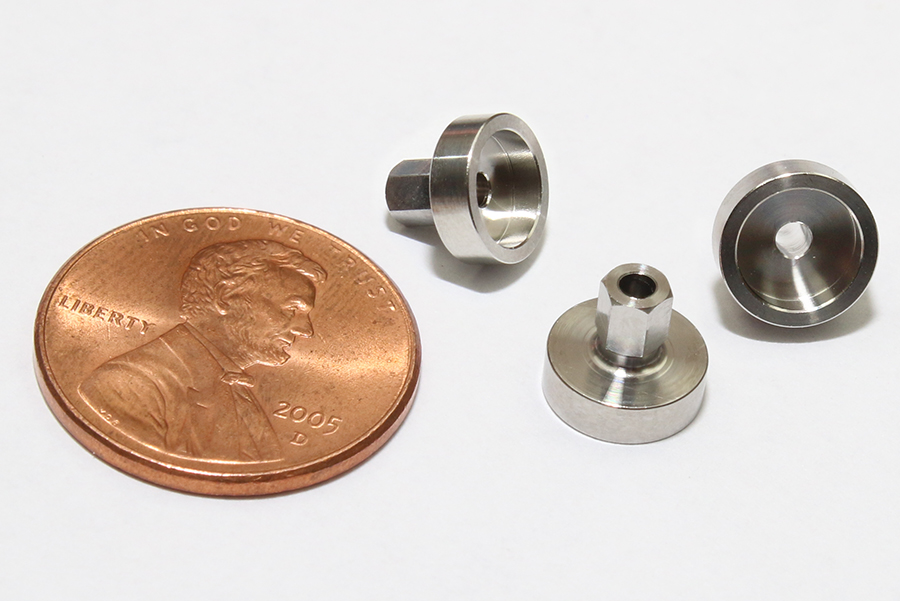

An aeronautics manufacturer was in need of a tiny stainless steel component. The part had an intricate design with a hexagon head and a tapered lip, a hole centered through the neck and a recessed base that needed to fit snugly with an adjoining part.

This stainless steel part was perfect for Boyer’s Swiss machining services. Boyer has the capability to machine multi-axis small parts with complex geometries. They also have the expertise to understand the metallurgical nature of the materials they are machining – 304 stainless steel in this situation. That expertise avoids delays and waste.

Boyer also has an extensive quality lab to ensure that rigid design specifications are met. Parts are inspected, tested and documented during the machining process. In this case, that included both the fit and finish of the part. This component was machined in one setup, inspected and cleaned before delivery.

If you are designing small metal or plastic parts, Boyer has the machining capabilities and expertise to produce the most complex parts. Their standard of quality and on-time delivery record makes Boyer the preferred machine shop for tiny, complex parts.