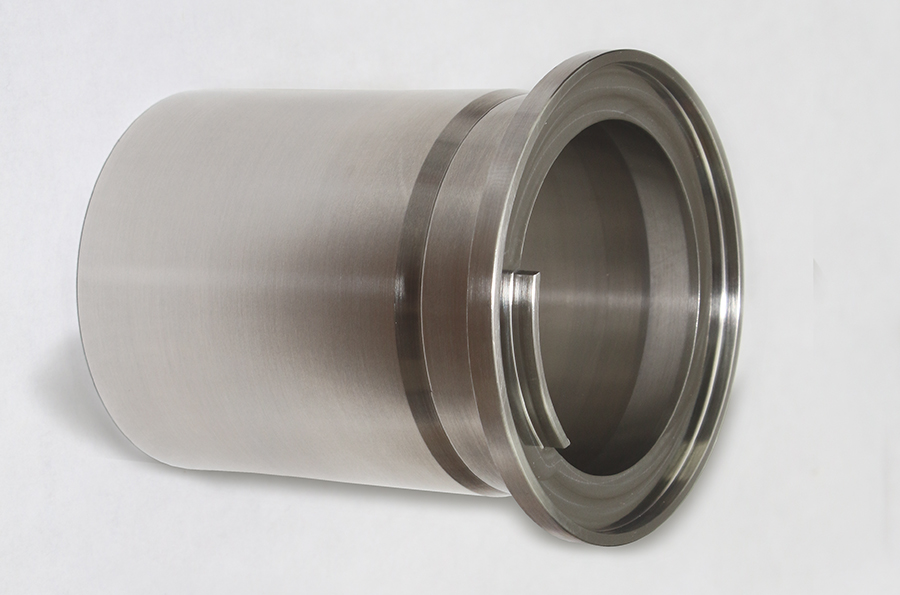

An aeronautics manufacturer was in need of a part milled from Inconel. The part was a cylinder designed with a very thin wall and an intricate lip that had a channel to accommodate a separate fitting and a thicker tongue to lock it in place. The part was cosmetically critical and had to be produced without any marks or marring.

Complex nickel superalloys, such as Inconel, are used in high stress and high heat applications because of their superior tensile strength. It has excellent corrosion resistance, which makes it a preferred material for aeronautic applications where the parts are exposed to harsh ambient conditions. However, Inconel is difficult to machine. Many machine shops would refuse to mill this kind of project. However, Boyer specializes in machining intricate metals and plastics. All machining and milling services are performed in-house to ensure quality control of each part. Parts go through rigid quality testing and documentation during production.

The aesthetics of this part were also critical. Each part had to be finished without any marks, including fingerprints or smudges. Boyer has the expertise and machinery to accommodate requests for cosmetically-critical and clean parts.

If you are in need of the machining of intricate parts fabricated from complex metals, or if you need an enhanced finish for your parts, contact Boyer, where quality is standard.