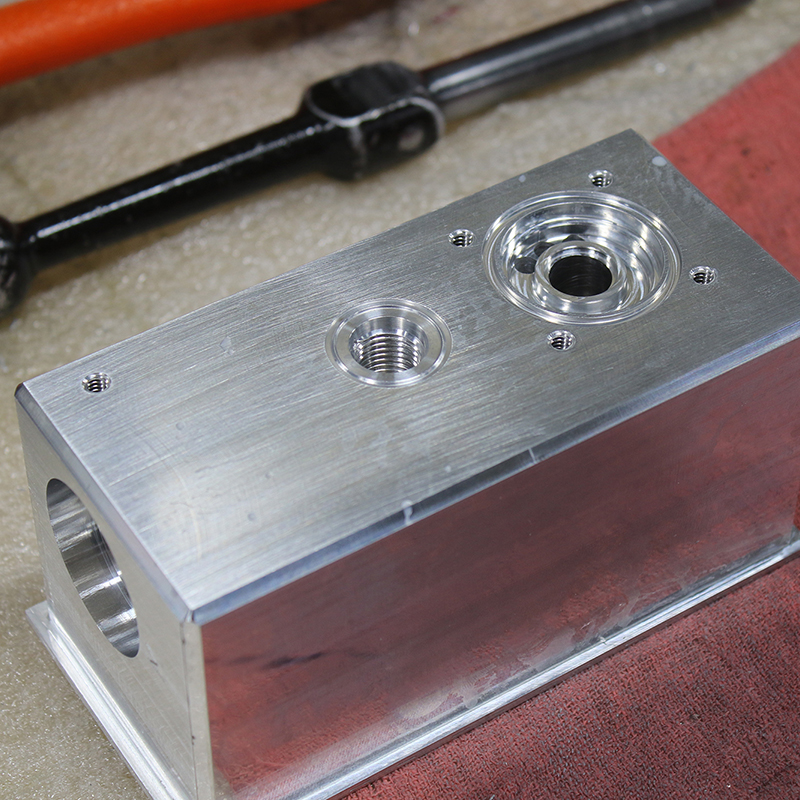

An engine manufacturer was in need of a valve body made with an aluminum alloy. The part was designed with O-ring ports for connecting fluid lines, bores for sensors and other components. They needed only a few hundred of these parts produced.

This part had very tight tolerances for the size and location of features that were critical to its function. For instance, the boring for the sensors had to be precise. Boring into an aluminum can be a challenge. If the cutting tool causes too much heat, the integrity of the aluminum will be compromised. It takes the correct equipment and an experienced journeyman to get the desired results. Other machine shops would outsource this type of machining. Boyer performs all machining and milling in-house in order to control our quality standards.

The part included a through hole for fluid lines and a perpendicular, recessed hole that intersected with it. It required seal surfaces with a good finish to stop any fluid leaks. The surface holes were finely threaded to secure other components. The part was machined with a beveled edge, all formed from the single aluminum block.

The customer also required these parts to be cleaned and tested to their specifications. Boyer has the ability to both ultrasonically clean parts and monitor the adherence to standards in their quality lab.

Boyer also specializes in medium-quantity runs. In this case, a few hundred were produced. Over the years, the manufacturing engineers have made slight changes to the part. Each time, Boyer has been able to adjust their machining to match precisely with the design.

If you are designing complex parts that necessitate multi-axis machining of difficult metals, take a look at Boyer Machine, where quality is standard.