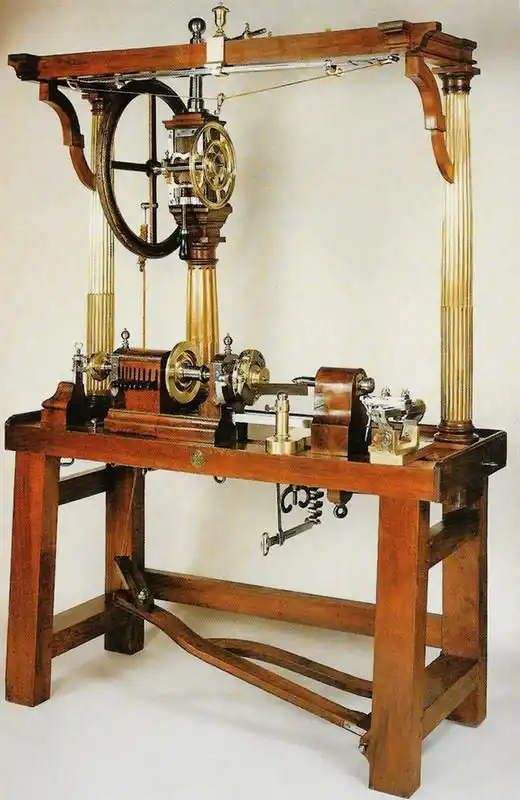

Early turning techniques date back to ancient civilizations, where artisans manually shaped materials like wood and metal using hand tools.

The industrial revolution in the 18th and 19th centuries introduced powered lathes that improved turning efficiency and precision.

Emergence of Numerical Control (NC)

In the mid-20th century, the concept of Numerical Control (NC) was developed, allowing machines to be controlled through a set of numerical instructions.

The development of punched tape and early computer systems facilitated the automation of machine tool operations.

In the late 1940s and early 1950s, the first CNC (Computerized Numerical Control )machines were developed, combining NC technology with early computers. John T. Parsons and Frank L. Stulen are credited with building the first CNC machine, which used punched cards to control its movements.

Machine turning has revolutionized the manufacturing industry since it was first introduced in 1952 in the form of the Cincinnati Milacron Hydrotel.

Throughout the latter half of the 20th century,turning technology continued to evolve rapidly, incorporating more powerful computers and software.

CNC turning machines became more accessible and widespread, revolutionizing the manufacturing industry with their precision, repeatability, and efficiency.

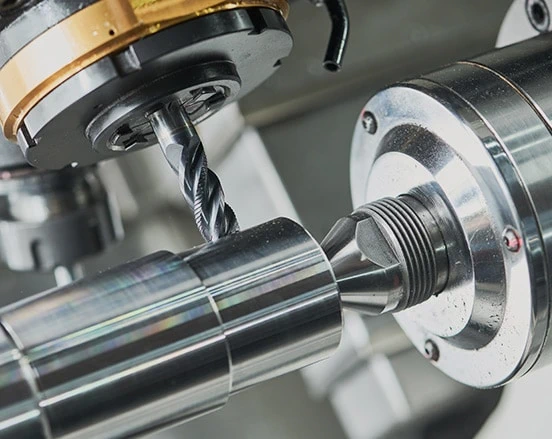

Modern Machine Turning

In the 21st century, CNC turning has become an integral part of modern manufacturing processes.

Advancements in robotics, artificial intelligence, and real-time monitoring have further enhanced CNC turning capabilities, making it a crucial component of the Industry 4.0 revolution.

What Can Boyer Do?

Boyer Machine & Tool Co., Inc.’s investment in an all-CNC turning process offers our customers a high-quality source for custom precision parts. We can also manufacture custom manufactures industrial parts with our CNC Milling processes..