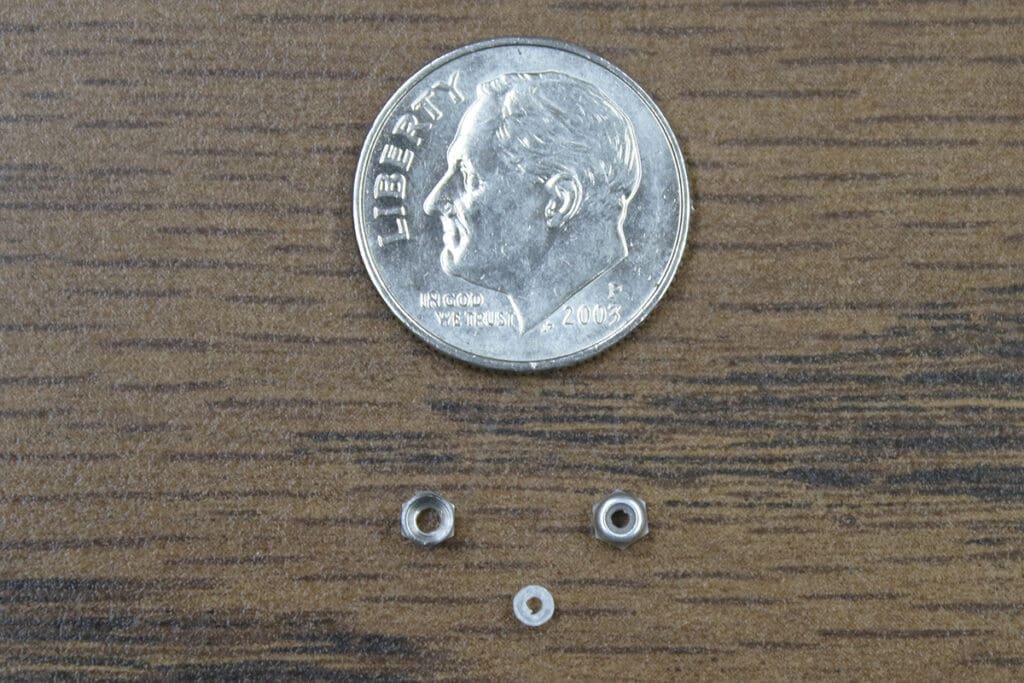

An aerospace manufacturer was in need of very tiny nuts for an assembly. The nuts were specified to be built with 303 stainless steel. But the very tedious process also required the tooling of a nylon insert that would be placed precisely inside each nut.

Boyer specializes in machining both complex metal and plastic parts. They have the ability to mill intricate parts, such as these very small aerospace parts. In this case, the stainless steel part was milled with a hex head and then counterbored to hold the insert. Instead of using an injection molded method to create the insert, the nylon part was laser cut. This creates a tighter and more exact fit between the two parts.

Boyer also assembled the two parts for the customer. The nylon insert was fixed in the stainless steel nut to specifications. The parts were also electrostatically cleaned and inspected for quality control before being packaged and delivered. All Boyer parts are cleaned, tested and documented before being shipped out.

If you are looking for a fabrication solution for intricate parts using either machined metals or plastics (or both), contact Boyer where quality is standard.