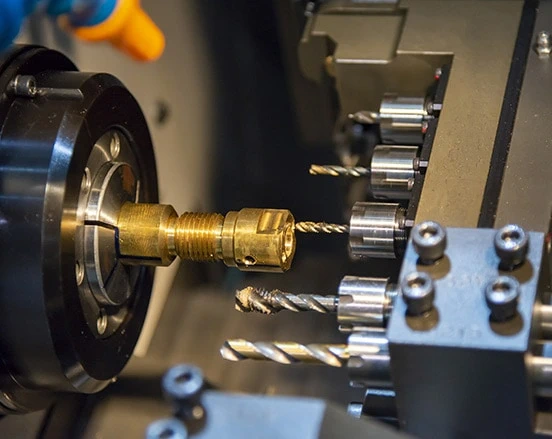

With our complete line of Citizen-Cincom Swiss screw machines, Boyer Machine & Tool Co., Inc. can fabricate custom threaded parts for prototyping or high volume production batches. By utilizing Swiss turning machines with (5) axis, overlapping tool post operations, and high speed threading functions, our experienced employees are capable of producing miniature custom nozzles, spacers, screws, drive shafts, and pins with diameters of up to 1 1/4″ and lengths of 12 1/2″.

With the combination of faster rapid traverses, higher spindle speeds, less vibration, and automated bar feed systems, the Citizen-Cincom machines are more efficient and precise than other turning processes. Using the latest quality procedures and equipment, quality control plays an essential role at Boyer from the first part through final inspection. This translates into production cost savings that maintain our competitive pricing advantage.

Boyer Machine & Tool ensures a quick lead time by performing a detailed part compatibility analysis with our Esprit, AutoCAD, and SolidWorks design software programs. Our experienced engineering staff will advise on modifications that will reduce production costs and increase the part’s functionality requirements.

Our Swiss Maching Service is suitable for the following industries:

- Aerospace

- Automotive

- Commercial Manufacturing

- Diesel Engines

- Electronics

- Medical/Health Care

- Military

- Research

Equipment

(2) Citizen-Cincom C32 Vlll

(1) Citizen-Cincom L32 VIII

(1) Citizen-Cincom L20XII

(1) Citizen-Cincom L20 VII

(1) Citizen-Cincom K16E VIIP

(2) Citizen-Cincom L12 VII

Tolerances

Positioning Accuracy: +/-0.0001

Repeatability: +/-0.0005″